Electric Chain Block Uses: What Are Electric Chain Hoist Uses?

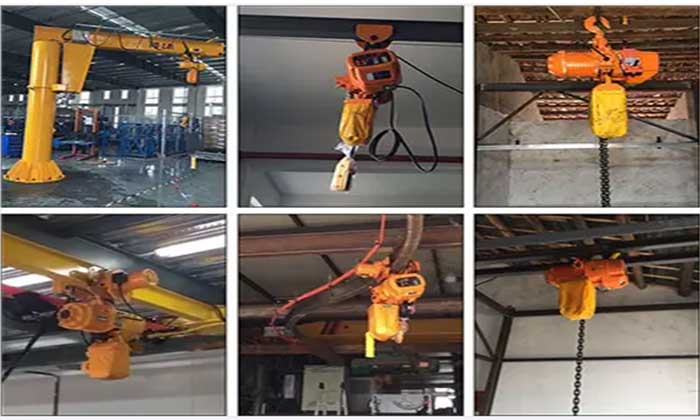

What are electric chain block uses? Equipped on overhead chain hoist crane, gantry chain hoist crane, jib chain hoist for various industrial applications, such as, ware house, factory, workshop or outdoor applications, etc. If you need an electric chain block for your particular electric chain block, please feel free to contact us.

What is an electric chain block?

An electric chain hoist is a lifting device that helps to hand objects that are too heavy, awkward, or fragile for you to lift on your own. The electric chain block is mainly consisted a motor on the top that lifts the chain, allowing you to hoist a heavy load to a higher position.With electric power, the electric chain block can largely reduce the

amount of effort required of the working staff , which will result in increased convenience and fewer injuries during material handling.

Why use an electric chain hoist?

Lifting heavy objects or materials at a warehouse or factory usually does not necessitate the employment of a single piece of lifting machinery. Forklifts, pallet jacks, and cranes are just a handful of the lifting machinery options accessible to you. Why would you want to utilize an electric chain block?

The primary benifit is probably safety, as use of electric chain blocks can greatly reduce the danger of injuries; this is due to the fact that the powered chain block and electric chain hoist takes all of the weight, not the user, and we all know how easy it is to strain your neck or back by incorrectly manual lifting even the lightest load. This gets us to the next cost-effective advantage: electric chain blocks are cost-effective because, first and foremost, they do the lift that may have taken three or four men or more to complete, hence lowering the amount of labor required.

Thirdly, as a result of the significant reduction in injuries, there will be less time off sick, resulting in no reduction in personnel and no need for sick pay. If you take care of your electric chain hoist, it should last a long time. Any faults should be easy to fix, and a skilled engineer should test and inspect it every 6 to 12 months to certify its safety for usage.

What is an electric chain block used for?

An electric chain block can be utilized for a number of different jobs and applications. The electric chain blocks are primarily used in various types of facntries and plants, storage, wind-power stations, logistics, ports, the construction field, and other places or workshops for loading and unloading in factories, warehouses, or other workshops for machinery installation, dispatching loads and equipment maintenance with capacities of 500 kg, 1 ton, 2 ton, 3 ton, 5 ton, 10 ton, 20 ton, 35 ton, and customized.

Single girder electric chain hoist crane

The electric chain hoist crane is a single girder overhead travelling crane, equipped with electric chain hoists as the hoisting system for material handling with capacity up to 16 ton.Contact us to get customized single girder electric chain hoist crane.

Double girder electric chain hoist crane

The double girder electric chain hoist crane is a double girder overhead crane, equipped with electric chain hoists and hoist trolley as the hoisting system for material handling with capacity up to 32 ton or above with customized hoist crane designs. Contact us to get customized double girder electric chain hoist crane.

Slewing jib chain hoist cranes

Slewing jib hoist cranes is ideal for short distance material handling, with various designs and configurations are available such as free standing jib hoist crane, wall mounted and wall travelling jib hoist crane, and port jib hoist crane, etc. Contact us to get customized slewing jib electric chain hoist crane.

Motorized chain hoist kbk crane

Motorized chain hoists are perfect for light duty kbk cranes, monorail kbk cranes , suspension kbk crane, and free standing kbk crane either in flexible crane configuration or in rigid crane configurationl. Contact us to get your customized kbk electric chain hoist crane.

A frame gantry electric chain hoist crane

For A frame gantry cranes, electric chain hoists also can be used as the hoisting system of a single girder gantry crane design and a double girder gantry crane design with a double girder hoist trolly. Contact us to get customized A frame gantry electric chain hoist crane.

Portable gantry electric chain hoist crane

Manual trolley electric chain hoists are widely used with the portable gantry crane or small gantry cranes which is for light duty material handling. With your requirement, the electric motor chain hoist portable gantry cranes are also available. Contact us to get customized portable electric chain hoist crane.

- Electric chain blocks and chain blocks are appropriate hoisting solutions for applications with limited headroom, high-production working conditions, and workshops or workstations that require periodic lifting and adjustment. Electric chain blocks are frequently used on overhead hoist cranes, gantry hoist cranes, jib hoist cranes, monorail hoist cranes, H & I beam cranes, and other cranes with various mountings, such as hook mounted, lug mounted, and trolley mounted. All of our electric chain block cranes may be tailored for your individual configuration and deliver excellent and dependable results, maximizing the return on your investment!

- Electric chain hoist overhead crane with single girder or double girder design for workshop and warehouse for various types of loads handling.

- Jib hoist cranes or workstation cranes that are free-standing or wall/pillar mounted are appropriate for applications where material handling is centered in a specific working area and can rotate up to 360 degrees.

- A monorail chain hoist crane is a light overhead single beam crane that is used in applications such as factory automation and production lines. It can be straight or curved.

- An A frame gantry hoist crane is an I-beam or box-shaped girder that runs on ground tracks in a designated location to help with the handling of big loads.

The electric chain blocks can work with a variety of overhead traveling cranes to satisfy your material handling needs in a variety of applications while maintaining excellent safety and efficiency. For you, electric chain block cranes will be a fantastic and cost-effective choice. Please contact us to see if there is a potential we might save you money.

As a motorized chain block manufacturer and supplier , we can ensure that your electric chain blocks cranes are performing at their optimum and are well suited to your application requirements. Please contact us if you require electric chain blocks, either geneal use powered chain hoists or custom made electric chain blocks with features such as spark resistance, explosion proof, or others.

What are the advantages of employing an electric chain block instead of a forklift?

A electric powered chain hoist can replace forklifts, which is advantageous because forklifts require two people to operate: one to drive and the other to steer. " A forklift is also riskier because it works in close quarters and its movements aren't as precise, resulting in damage to the object being lifted. These kinds of complications aren't a problem with an electronic chain block."

Nobody has to worry about lugging something up a flight of stairs or using a forklift with an electric chain block to save time and energy. Furthermore, because an electrical chain hoist only takes one person to operate, the other workers can concentrate on other aspects of the job.

What industries use electric chain blocks?

- Electric chain blocks are mostly used in the electrical and construction industries. Lifting items from one floor to another in a safe and effective manner is crucial when it comes to getting the task done efficiently and on schedule.

- An electric chain block has shown to be incredibly valuable in the medical area. If a patient is otherwise bedridden, it can be used to help them go onto a stretcher or change their bedding.

- Many people utilize electric chain hoists in general production and appreciate the benefits it has brought to their workflow and safety ratings.

- For construction industry, motorized chain block comes in handy during construction and electrical work since it allows you to carry objects to the roof or another floor quickly and effortlessly.

- For one thing, it comes in handy during construction and electrical work since it allows you to carry objects to the roof or another floor quickly and effortlessly;

Six tips on electric chain block Usage

1, Installation of an electric chain block.

Electric chain blocks are frequently installed on the I-beam track, and the track must be fitted at both ends of the block to prevent misuse and hoist derailment. It is best to have a height at both ends of the I-track orbit, a dependable durable cushion or a baffle with a rubber block, and the I-beam track should not extend outside. Optional design, a rain protection device can be installed if the electric chain block is used for outdoor application.

2, I-beam track to meet the grounding line criteria.

When someone touches the hook and the I-beam rail ground wire cross-sectional area is too small or there is no ground wire, there is a risk of electric shock. As a result, the I-beam rail grounding wire must be connected; the specifications are normally 4-5mm diameter bare copper or a cross-section of not less than 25mm flat steel, and it should be patrolled on a regular basis.

3, the proper application of limiters and guide rope.

The limiter limits the lift of the electric chain block, preventing the hook from rising too high against the reel or descending too quickly to pull the wire rope off. The rope is mounted on the sleeve of the rope slot and rotates axially with the sleeve to align the wire rope on the sleeve and collide with the stop plate on the lever, ensuring the safe operation of the electric chain block. Limiter, guide rope are essential electric chain block security accessories that may effectively avoid top bad guards and litter accidents.

4, proper wire rope refueling maintenance techniques

The proper way of refueling is to apply oil ( steel wire grease or thin oil is your choice but not the butter, which should not be used ) to the reel or pulley on the subject of the vertex, so that it is naturally sucked into the rope.

5, stick to a mobile method of operation.

Some of the electric chain hoist units used to improve the operator's working conditions will be put in the hoist on the control box moved to the wall fastened, the operator can sit in the chair "remote control command," at the same time, increasing the likelihood of an accident. As a result, the control box to be put in the electric chain block, the control line cannot be too lengthy, so that operators in horizontal operation with the gourd movement, both at any moment to supervise the functioning of equipment, but also to avoid accidents.

6, rigorous adherence to a regular maintenance system.

Electric chain blocks and other lifting equipment must be maintained on a regular basis in accordance with safety rules. Wear parts must be replaced on a regular basis, in addition to ordinary maintenance of the gourd (including the repair of electrical components). Overhaul, to rigorously adhere to debugging methods, qualified before usage.

Choosing a reliable electric chain block

Finding a reliable manufacturer and supplier of electric chain hoists is one of the most critical stages. However, it is also critical to consider the variables listed below in order to make the best decision.

- Load weight- The weight to be lifted dictates the hoists you need to purchase.

- Lifting speed- You must tune it to ensure the successful loading and unloading of goods.

- Your working environment- Certain production settings might cause abrasion to your machines. For example, if the temperature is extremely high, your hoist may begin to malfunction. Similarly, extremely low temperatures cause cracking and freezing of internal parts. Another risk to your system is frequent temperature fluctuations, which can lead to short circuits.

- Hoist height- You wish to lift your load to a certain height. This is a key consideration when selecting a hoist model. A container with an electric hoist is available. The higher the height, the longer the chain and the larger the container. However, too many huge containers can become a stumbling block in your load lifting operation.

- Duty cycle- The duty cycle shows the length of time you will utilize the hoist. This element is linked to longevity. As a result, one of the most significant factors is the duty cycle length, as your system must dissipate heat from motors.

- Hoist height- You need to lift your load to a certain height. This is a key consideration when selecting a right motorized chain hoist model. A chain container is consisted in the composiste of the electric chain hoist. The higher the height, the longer the chain and the larger the chain container. However, too many large chain containers can become a stumbling block in your load lifting operation.

- Duty cycle - The duty cycle shows the length of time you will utilize the electric chian hoist. This element is linked to longevity. As a result, one of the most significant factors is the duty cycle length, as your system must dissipate heat from motors.

EOTCRANEKIT is a leading manufacturer of electric chain hoists, chain pulley blocks, manual trolleys, and overhead chain hoist cranes. You must choose the the most suitable type of model for your company depending on your lifting requirements and application. Furthermore, you must be familiar with the technical specifications of the powered chain hoists you intend to use.